Piping Works

At Ciest Metal, we specialize in comprehensive piping works for industrial applications, offering tailored solutions that ensure safety, efficiency, and compliance with international standards.

Expert Piping Services

Our experienced team provides a full spectrum of piping services, including:

Design and Engineering: Tailored designs for complex piping systems.

Fabrication: Precision manufacturing of pipes and components.

Installation: Expert assembly of piping systems on-site.

Maintenance and Upgrades: Ensuring optimal performance and longevity of existing systems.

Machinery We Use at Ciest Metal:

Roundo R6S Profile Bending Machine

The Roundo R6S Bending Machine is a versatile and reliable solution for precision profile bending in metal fabrication and industrial manufacturing. Designed to handle a wide range of materials and section types, the R6S delivers accurate, repeatable results for both light and heavy bending applications.

The Roundo R6S excels in bending multiple metal profiles, including angle iron, flat bars, channels, and pipes. Its robust construction and controlled bending process make it ideal for forming complex shapes while maintaining material integrity and dimensional accuracy.

Profiles the Roundo R6S Can Bend:

External and Internal angle iron

Flat iron and flat iron on edge

Solid square and round bar

Pipes and square tubes

IPE and HEA beams

UPN channels

The Roundo R6S profile bending machine is widely used in metal fabrication shops, structural steel production, construction, and industrial applications, where precision, durability, and efficiency are essential.

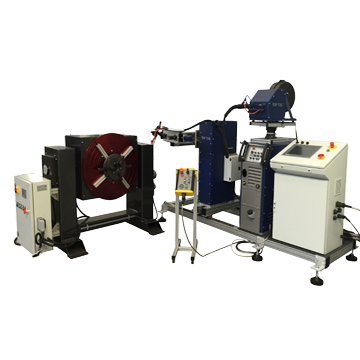

TiPTiG Automation System KD/HD - for advanced TIG Welding Services

At Ciest Metal, we provide high-precision TIG welding services using the TiPTiG Automation System KD/HD. Our advanced welding automation solution ensures consistent, high-quality welds for industrial applications, including pipe welding, flange connections, elbow welds, and cladding operations.

The TiPTiG DV System KD/HD delivers a linear, continuous, and stepless wire electrode movement combined with a secondary oscillating motion. This generates kinetic energy that moves the weld pool dynamically, improving weld quality and consistency. The system also features wire preheating via resistance, ensuring process stability and reducing defects.

Key Features:

Beckhoff Control Unit with programs for:

Pipe butt welds

Flange-to-pipe connections

Pipe-to-elbow welding

Internal and external cladding

Stable aluminum profile base – mobile or with adjustable feet

Precision linear guides and slides for X-Y-Z axes with trapezoidal spindle, OSC oscillation, and stepper motors

Automated TIG torch holder and swivel system for fine adjustments

Integrated TIG power source (TIG 500iDC/160HW, HD version)

Rotating welding table for complex weld orientations

Why Choose Our TIG Welding Services?

High repeatability and process reliability for all welding projects

Dynamic weld pool control for superior quality

Capability for multiple materials: steel, duplex alloys, copper, titanium, and more

Efficient, faster production with reduced rework and downtime